The Peasant Arts Guild published a booklet

Rainbow Secrets by Catherine A. Jones, a copy of which is held by the Haslemere Educational Museum. The booklet has the

17 Duke Street, Manchester Square address for the Peasant Arts Guild.

|

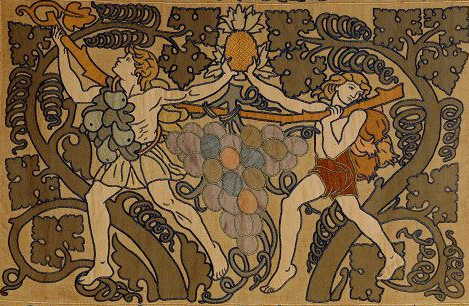

| Jones, Catherine A., Rainbow Secrets, The Peasant Art Guild |

In the 1901 census Catherine Jones is recorded as living in Honey Hill, Foundry Lane, the house which sits behind the Dye House on Kings Road. Jones is described as a linen and cotton hand weaver. In various other Peasant Arts documents, Jones is identified as the joint manager of the Weaving House, the joint curator of the Peasant Arts Museum and also the Treasurer of the

New Crusade Toy Industry for Unemployed Women.

Rainbow Secrets is subtitled 'Recipes for colouring wool in simple and homely ways', It states on the front page:

"Before these secrets can be revealed the fleece must be cleansed and careful attention given to the following general instructions in Weaving, Mordanting and Dyeing Wool,

1. To succeed in producing bright colours soft water is a necessity. In washing as well as dyeing hard water is altogether injurious to wool,

2. A handful of bran boiled in the water required for 1 lb of wool will have a good softening effect,

3. Wool must not be washed in very hot water,

4. Wool must never be squeezed tightly when wet; heavy handling makes it matted and hard,

5. Mordanted wool must be kept covered until wanted for the dye bath, as light affects it unfavourable,

6. Wool must always be damp when put in to mordent or dye,

7. Some few dyes (Crotal is one) and mordants only can be safely used in iron pans; enamelled or zinc pans were safe for all,

8. The more care and attention that can be given to each process, the more satisfactory will be the result.

How to Wash Wool

1. Pull the fleece apart.

2. Soak in cold water for 24 hours.

3. Make a good lather with soft soap or Lux in warm water.

4. Take a small portion of the fleece, shake it about well in the lather until all dirt and grease are removed. Squeeze lightly and rinse thoroughly in clean warm water.

5. Repeat this process till all the fleece is washed.

6. Hang out to dry. Do not dry by a fire."

I wonder where the dye baths were situated? And how big these would have been? Where would the fleeces have been hung out to dry? Maybe in what is now my garden, on the edge of the old Foundry Meadow.

The rest of the book seems to follow some similar content to the previous dye book and Skilbeck booklet I have posted on. It begins with:

"

How to Dye with Madder

Madder is the dried and ground-up root of a plant, Rubia linetorum, from which beautiful red and orange colours are obtained.

It requires a mordant to prepare the wool to receive the colour. The mordanting must precede the dyeing.

|

| Jones, Catherine A., Rainbow Secrets, The Peasant Art Guild |

Mordanting. For 1 lb, wool take 5 ozs. Alum and 1 oz Cream of Tartar. Put Alum and Tartar into pan, not iron pan, and dissolve in enough water to cover wool well.

Take the clean, damp wool and put in the solution.

Heat and boil one hour(?) stirring occasionally.

Leave wool in mordant till cold (a day's soaking will not spoil it).

Lightly squeeze out and put away in linen bag (protected from light) for four or five days when it will be ready for dyeing.

Dyeing. Bright red.

8ozs Madder for 1lb wool

Soak Madder overnight in water.

Next day put in pan (not iron pan), with enough water to cover wool.

Before the wool is put in this pan, heat the Madder to boiling-point, but do not boil it: boiling darkens the colour.

Put the mordanted wool into this pan of heated dye-liquid, and keep just below boiling-point for one hour.

Stir well with a stick in order that all parts of the wool may absorb the colour.

Remove from the dye, wash well in several changes of warm water, and hang out to dry.